Monitoring system for thermal wells with temperature and level measurement

The monitoring system developed for thermal wells enables continuous and reliable measurement of key hydrothermal parameters, with a particular focus on temperature and water level. The project includes the use of dedicated sensors and a modular data logger, suitable for harsh environments, to ensure high performance and long-term stable operation, even under extreme climatic and hydrogeological conditions.

Sensors and Installation

The sensor configuration is designed based on the specific characteristics of each well. The measurement ranges for temperature and level are selected to cover the expected operational range, optimizing accuracy and measurement resolution.

- The level sensor is installed near the surface, just below the wellhead, and detects the water column using a piezometric or absolute pressure principle. This allows for the continuous monitoring of static and dynamic level variations of the thermal fluid, which are crucial for analyzing the behavior of the geothermal reservoir.

- The temperature probe is lowered to depths up to 400 meters using a reinforced high-temperature cable capable of operating at temperatures up to 125°C. The sensor is hermetically sealed to withstand hydrostatic pressure and potential chemical agents in the thermal fluid. The shielded and waterproof cable allows lossless signal transmission even over long distances.

The sensors are connected to a FlexLog data logger, a modular, rugged, and low-power system designed for environmental and geotechnical monitoring applications.

Technical Features of the FlexLog

- Self-powered, compatible with solar panels or long-life batteries.

- Modular design with expansion options via 4-channel differential or 7-channel single-ended modules.

- Analog inputs (4–20 mA, 0–10 V), digital inputs, PWM or frequency counters, and serial interfaces (USB, RS232, RS485, SPI).

- Local memory on removable SD card, enabling data recording even without connectivity.

- Integrated modem (GSM/GPRS/UMTS) with a universal roaming SIM card, for automatic data transmission to a remote platform.

- IP67 enclosure made of high-strength technical plastic, with sealed connectors allowing sensor maintenance without disconnecting the entire system.

- LED indicators, manual activation button, and internal battery voltage control for efficient power management.

The FlexLog data logger communicates with the METRA web platform, a dedicated cloud interface for data visualization and remote management.

The METRA platform offers:

- Secure remote access via web browser, also available on smartphones and tablets;

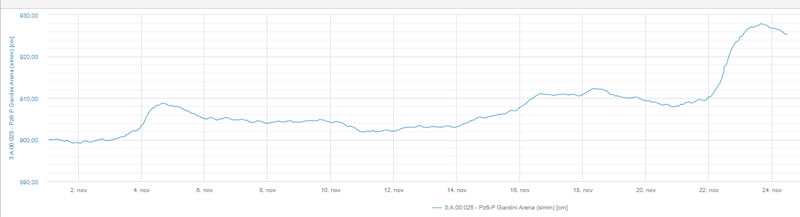

- Configurable charts, updated in real time and organized by parameter and measurement station;

- Georeferencing of stations, enabling precise monitoring of each site;

- Alarm threshold settings and automatic email notifications in case of anomalies such as transmission failure, low voltage, or sensor interruptions;

- Advanced user management with customizable permissions, allowing personalized and controlled access to data.

Thanks to the integration of high-reliability sensors, a flexible acquisition system, and an advanced cloud platform, the system is ideal for the continuous monitoring of thermal wells in both industrial and research applications, offering fully autonomous operation over long periods while minimizing the need for manual intervention.

Level Sensors – Technical Features

The level sensor used for thermal well monitoring is designed to ensure reliability and accuracy, even in harsh environmental conditions. It is installed near the surface at the wellhead, with measurement performed in the liquid column using the piezoresistive principle.

The sensor's compact structure, entirely made of AISI316L stainless steel, makes it especially robust and suitable for extended use in aggressive environments. The mechanical design is of the “sealed cap” type, made of POM (Polyoxymethylene), a material resistant to corrosion and wear.

- Allowable overpressure of at least 3 times the full scale (minimum 3 bar), to protect against accidental pressure spikes;

- Standard output signal of 4…20 mA, compatible with most industrial data acquisition systems;

- Power supply range from 9 to 33 Vdc, with wide tolerance for DC systems;

- Measurement accuracy ±0.2% FS TSL, according to DIN16086 standard, with fixed zero point, including hysteresis and repeatability;

- Temperature compensation range from -5°C to +80°C, with operational tolerance up to +100°C;

- Viton seals, ideal for chemically aggressive environments;

- Connection cable in PE or FEP, equipped with a barometric compensation tube to correct for atmospheric pressure variations. Cable length is provided upon request based on site installation depth;

- Calibration certificate traceable to 5 points, ensuring the sensor’s metrological quality.

These features make the sensor an extremely reliable instrument for level measurement in geothermal wells, ensuring long-term stability, mechanical resistance, and compliance with environmental and regulatory requirements in the sector.

Conductivity, Temperature, and Pressure Probe

Technical features of the combined sensor (level / temperature / conductivity):

Level / Pressure Measurement

- Sensor: ceramic, temperature-compensated

- Available measurement ranges: 0…4 m, 0…10 m, 0…20 m, 0…40 m, 0…100 m water column

- Resolution: 0.01% FS

- Accuracy: ≤ ±0.05% FS

- Long-term stability: ≤ ±0.1% FS per year

- Zero drift: ≤ ±0.1% FS

- Overpressure resistance: ≥ 4 times full scale (no permanent damage)

Temperature Measurement

- Sensor type: NTC

- Measurement range: from –25°C to +70°C (non-freezing)

- Calibrated range: from +5°C to +45°C

- Resolution: 0.01°C

- Accuracy: ±0.1°C

- Available units: °C, °F

- Temperature-compensated operating range: from –5°C to +45°C (liquid only, non-freezing)

- Available units: m, cm, ft, mbar, psi

Electrical Conductivity

- Sensor: 4-electrode graphite

- Measurement range:

- 5 … 2,000 µS/cm → resolution: 1 µS/cm, accuracy: ±1 µS/cm or ±0.5% of value

- 0.1 … 100 mS/cm → resolution: 0.01 mS/cm, accuracy: ±0.01 mS/cm or ±1.5% of value

- Calibrated range: +5°C … +45°C

- Temperature compensation: freshwater, brackish water, standard methods (e.g., ISO 7888)

- Salinity calculation: standard methods (including USGS 2311)

Electromagnetic Flow Meter

This electromagnetic flow meter is designed for the accurate and reliable measurement of conductive liquids, even in the presence of suspended solids. Its robust structure and advanced features make it suitable for a wide range of industrial applications.

Version with internal TEFLON lining

Main Features:

- Measurement technology: Electromagnetic, suitable for liquids with conductivity above 5 μS/cm.

- Measurement range: From less than 0.1 m³/h up to over 110,000 m³/h, with fluid velocity up to 10 m/s in both directions (bidirectional measurement).

- Accuracy: ±0.5% standard; ±0.2% optional.

- Remote version: -10°C to +80°C (rubber), -40°C to +150°C (PTFE).

- Repeatability: ±0.1%.

- Internal lining materials: PTFE for DN10–DN500; rubber for DN65–DN2000.

- Electrode materials: Stainless steel 316L, Hastelloy C, Titanium, Tantalum, Platinum.

- Sensor material: Stainless steel 321.

- Enclosure material: Epoxy-painted aluminum.

- Power supply: 85–265 Vac, 24 Vac/dc, 12 Vdc.

- Power consumption: Typical 6 W, maximum 8 W.

- Outputs: 4–20 mA, frequency output (0.1–10,000 Hz), pulse output, alarms via relay.

- Communication interfaces: Modbus RTU, HART, Bluetooth (optional).

- Integrated datalogger: Data storage on USB flash drive, with configurable logging interval from 15 to 3600 seconds.

- Analog inputs: Two active 24 Vdc inputs for 2-wire transmitters (e.g., temperature or pressure).

- Digital input: For integrated batch function.

- Protection rating: IP67 for compact version; IP67/IP68 (on request) for remote version.

- Process temperature: Compact version: -10°C to +80°C (rubber), -40°C to +100°C (PTFE).

- Storage temperature: -40°C to +85°C.

- Relative humidity: 0–100% RH up to 65°C, non-condensing.

Advanced Functions:

- Reverse flow measurement.

- Output testing (current and frequency).

- Anti-condensation filter installed on the converter.

- OLED display, removable and rotatable by 90°.

Typical Applications:

- Integrated water cycle.

- Food and beverage industry.

- Chemical and pharmaceutical industry.

- Wastewater treatment.

- Mining and metallurgy industry.