Pressure cells

Pressure cells

Pressure cells are used to monitor stresses acting at the interface between a retaining structure (such as tunnel steel arch supports) and the surrounding active soil pressure.

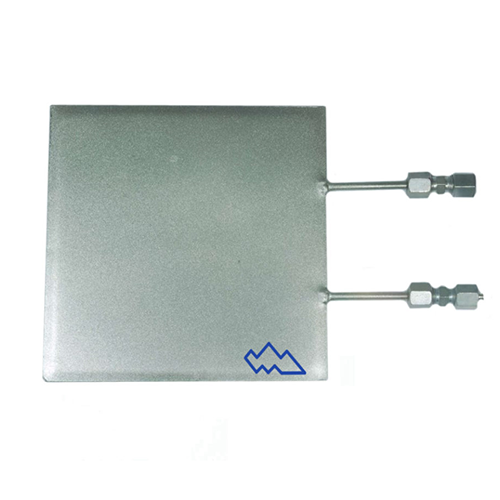

The pressure cells consist of a rectangular-shaped steel diaphragm filled with special oil and connected to an electric transducer, which converts every pressure variation acting on the diaphragm into a standard electrical signal (4–20 mA).

Designed in multiple versions for high versatility and adaptable to various installation needs, they are available in different configurations:

- Without hydraulic tubing, with the transducer mounted directly on the cell, either horizontally or vertically

- With hydraulic tubing for preloading and the transducer mounted either directly on the cell or on the tubing

Notably, the second type of pressure cell features the ability to be re-pressurized via a recharge valve installed at the end of the standard 1.5-meter Rilsan hydraulic tube.

Re-pressurization becomes necessary, for instance, when the diaphragm is embedded in the concrete lining of a tunnel, which may shrink during curing, resulting in loss of contact between the diaphragm and the concrete.

A re-pressurization operation allows the instrument to function properly by restoring full contact between the diaphragm and the concrete surface.

The electric pressure transducer’s readings can be acquired either through a portable control unit or via an automatic data acquisition system designed for continuous monitoring.

- Technical data sheet:

G1 - Pressure Cells