Inclinometric technology for monitoring deep slope movements: automatic systems and high-precision probes for geotechnical risk management

In the field of applied geotechnics and hydrogeological risk management, assessing deep ground movements is one of the most complex and relevant challenges. Landslides and deep-seated instabilities do not always present immediate surface signs but can progress slowly over months or years, generating deformations that endanger infrastructure, underground works, and residential areas.

In this context, inclinometric technology has been the reference standard for decades for the continuous monitoring of horizontal displacements at depth.

What is an inclinometer and what is it used for?

An inclinometer is a device designed to measure the horizontal deformation of the ground along a specially drilled borehole. The operating principle is based on detecting tilt variations of the probe inside a guiding casing inserted into the borehole. These variations are converted into horizontal displacements through differential calculations, providing a precise reading of the subsurface ground behavior.

This type of measurement allows you to:

- identify the slip surface position within the unstable mass;

- quantify the cumulative displacement over time;

- define the deformation profile and its evolution.

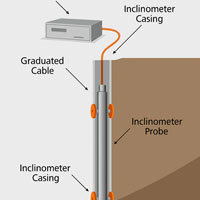

What does an inclinometric system consist of?

A complete inclinometric system generally consists of:

- Inclinometer probe: about 60–70 cm long, made of stainless steel or titanium, equipped with triaxial accelerometric sensors;

- Inclinometer casing: plastic tube (PVC or ABS) with internal orthogonal double grooves that guide the probe inside the borehole;

- Graduated electrical cable: allows for the precise positioning of the probe at known depths;

- Datalogger or control unit: for data recording, with options for local storage or remote transmission.

Measurements are taken at regular intervals (e.g., every 50 cm or 1 meter), ascending vertically along the borehole. Repeated readings over time allow comparison with the initial measurement (baseline) to generate differential and cumulative displacement curves.

Advanced technologies: automatic inclinometers and IoT systems

Today, thanks to technological innovation, inclinometric systems can be fully automated. The main solutions available are:

- Digital inclinometer chains (MEMS): a series of rigid or flexible sensor modules placed along the entire length of the casing, providing continuous and simultaneous measurements;

- Robotic systems: motorized control units that move the probe along the casing and automatically send data to the control center via LTE or Wi-Fi;

- Integration with IoT platforms and cloud software: for remote management, data analysis, alert generation, and interactive dashboard visualization.

These technologies reduce the need for manual intervention, lower maintenance costs, and increase the frequency and accuracy of readings, making monitoring more safe, continuous, and scalable.